Fascination About Motorcycle Parts New Zealand Specialists

The 7-Second Trick For Motorcycle Parts New Zealand Specialists

Table of ContentsMotorcycle Parts New Zealand Specialists Can Be Fun For EveryoneLittle Known Questions About Motorcycle Parts New Zealand Specialists.Motorcycle Parts New Zealand Specialists for DummiesThe 20-Second Trick For Motorcycle Parts New Zealand SpecialistsThe Buzz on Motorcycle Parts New Zealand SpecialistsAn Unbiased View of Motorcycle Parts New Zealand SpecialistsThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is DiscussingWhat Does Motorcycle Parts New Zealand Specialists Do?

Get to out to one of our professionals today.CNC machining technology is swiftly ending up being the centerpiece of several various production procedures around the world as a straight outcome of its several advantages over other techniques. In addition, the markets that make motorbikes have actually hopped on board with this fad. The most ingenious business are currently establishing their engine components and wheels using machining strategies initially established for motorbike parts.

You might be asking yourself why we use. Now that we have your focus let us clarify the rationale behind this contemporary growth in the motorcycle manufacturing industry.

Excitement About Motorcycle Parts New Zealand Specialists

On top of that, you have full control over the look of the parts, even to the minute details. Occasionally, motorcyclists might decide to fix up their ride by mounting aftermarket parts or changing the bike's makeover. Once more, computer system mathematical control (CNC) machining is the most useful method. Upgrades might be of any type of form and design you want.

Things about Motorcycle Parts New Zealand Specialists

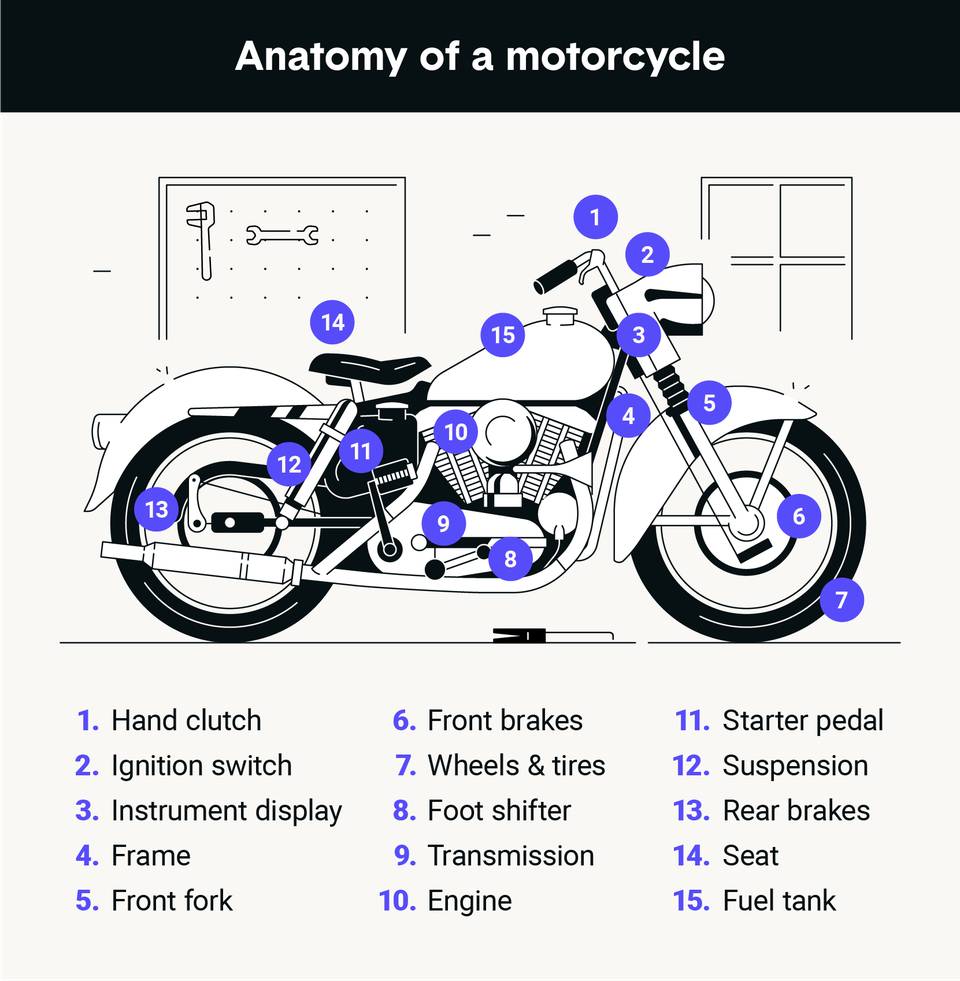

CNC machining may be utilized to make nearly all of a bike's steel and plastic parts. To proceed, we'll discuss a number of machined parts for motorcycles.

When customizing the wheels, the disks are where the emphasis ought to be. The majority of them are made out of aluminum. Aluminum alloys are popular for the exceptional machining capacities that they have. Milling treatments are utilized to get the desired degree of wheel modification. One more element of the motorbike that might be individualized is the tires.

The Only Guide for Motorcycle Parts New Zealand Specialists

When it concerns an automobile (or a motorbike), the most crucial component is the engine. Numerous individuals mention it as the "heart" of the vehicle. On the various other hand, the camshaft, the cyndrical tube head, and the pistons have a tendency to be elaborate and call for layouts with a high degree of precision.

Illumination is another complex aspect of modification. Use just top notch items, nonetheless, because these lights are crucial for the security of motorcyclists and various other drivers or people when driving, specifically during the night. Bike headlights have 3 main components: the bulb, or source of light, the lens, and the real estate. Particularly, we tailor the lens and the real estate.

Milling processes with a remarkable surface would cause the lenses having a reflective top quality that resembles that of a mirror. The cover, on the other hand, is not composed of fragile materials; rather, it is constructed out of challenging polymers that can be machined into more elaborate patterns.

Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

They typically have fancy geometries with a wide learn the facts here now range of minute information. Motorcycle suppliers often cast these parts, but only for the production of bespoke components. CNC machining is the technique of option when generating special items. Machining on 5 axes in today's globe is the methods through which any design form may be realized.

Choose Runsom for your tailored motorcycle components! We have the capacity to produce complicated and trendy parts making your motorcycle matchless.

Right here are a couple of examples of metals usually utilized in motorbike element machining. Aluminum is the primary material used by companies specializing in creating personalized motorcycle elements to develop a lot of these parts. In the past, we would certainly construct our engines out of cast iron. On the various other hand, aluminum is swiftly coming to be the product of choice, partly because of the reality that it is more lightweight.

Zinc refers to another metal that is very light in weight and has excellent machining top qualities because of its high mechanical stamina. This material might be created right into nearly any shape and maintains its measurements well. Also mission-critical components that require a high degree of precision might take advantage of their use.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

One more steel that sees hefty use in the production of CNC-customized elements is magnesium. It is amongst the lightest metals that are find more now obtainable and has exceptional machinability features and toughness compatible with its reduced weight. Among the disadvantages of magnesium is that its dirt might easily ignite.

Because of its remarkable machinability and weldability, stainless-steel is an alloy that is especially fit for CNC procedures. In addition to this, they have wonderful corrosion resistance and a high visual charm. Their most usual use in generating numerous motorcycle elements is bolts, such as screws and screws. Their reduced sensitivity to oxidation and rust makes them ideal for this usage.

Rumored Buzz on Motorcycle Parts New Zealand Specialists

It seems that browse around here CNC transforming and crushing are the foundational processes. In enhancement, it needs keeping bars of material, most frequently plastic or metal, in setting and then twisting a cutting tool to get rid of sections of the product as the product is transformed.

These methods are just as crucial and create parts with high accuracy and constant quality. The processes assist enhance the overall high quality of the machined bike elements.

The Basic Principles Of Motorcycle Parts New Zealand Specialists